Mwamakonda Makonda Investment Kuponya / mwatsatanetsatane Kuponyera Pampu Magawo

njira zamakono

Njira zamakono zopangira zitsulo zosapanga dzimbiri zoponyera pampu ndi motere:

1. Chifukwa cha kuchepa kwa madzi achitsulo chosungunula, pofuna kupewa kutsekedwa kozizira komanso kutsanulira kosakwanira kwazitsulo zosapanga dzimbiri, makulidwe a khoma lazitsulo zosapanga dzimbiri sikuyenera kukhala zosakwana 8mm;dongosolo la kuthira liyenera kukhala losavuta, ndipo kukula kwapang'onopang'ono kuyenera kukhala kokulirapo kuposa chitsulo choponyedwa;kuponyedwa kowuma kapena kuponyera kotentha kuyenera kugwiritsidwa ntchito.Kuponya nkhungu: Moyenera kuwonjezera kutentha kuthira, nthawi zambiri 1520 ° ~ 1600 ° C, chifukwa kuthira kutentha ndi mkulu, kutentha kwapamwamba kwa chitsulo chosungunuka ndi chachikulu, ndipo nthawi kusunga madzi madzi ndi yaitali.Komabe, ngati kutentha kukutsanulidwa kwambiri, kumayambitsa njere zowoneka bwino, ming'alu yotentha, pores ndi mchenga.Chifukwa chake pamapangidwe ang'onoang'ono, okhala ndi mipanda yopyapyala komanso yowoneka movutikira, kutentha kwake kumafika pamtunda wosungunuka wachitsulo + 150 ℃;Kwa kuponyera kwakukulu, kokhala ndi mipanda, kutentha kwake kuyenera kukhala pafupifupi 100 ℃ kuposa kusungunuka kwake.

2. Popeza shrinkage ya zitsulo zosapanga dzimbiri ndi zapamwamba kwambiri kuposa zitsulo zotayidwa, pofuna kuteteza shrinkage cavities mu castings, miyeso monga risers, chitsulo chozizira ndi zothandizira zimagwiritsidwa ntchito kwambiri popanga ndondomeko kuti akwaniritse sequential solidification.

Ubwino wa Zamalonda

Kuponyera ndalama kumatchedwanso kuponya molunjika / kutulutsa dewaxing.Poyerekeza ndi njira zina zoponyera ndi njira zopangira magawo, kuyika ndalama kuli ndi zabwino izi:

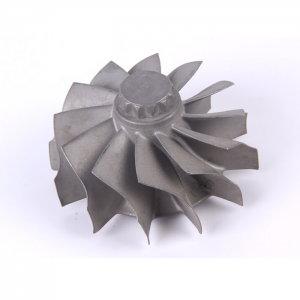

1. The dimensional kulondola kwa kuponyera ndi mkulu, pamwamba roughness mtengo wabwino, dimensional zolondola kuponya akhoza kufika 4-6 giredi, ndi pamwamba roughness akhoza kufika 0.4-3.2μm, amene akhoza kuchepetsa kwambiri processing chilolezo cha kuponya ndipo amatha kuzindikira kupanga kosatsalira.kuchepetsa mtengo wopanga.

2. Ikhoza kuponya ma castings okhala ndi mawonekedwe ovuta komanso ovuta kuwakonza ndi njira zina.Kukula kwachiwonetsero kwa ma castings kumayambira mamilimita angapo mpaka masauzande a millimeters, makulidwe ochepera a khoma ndi 0.5mm, ndipo m'mimba mwake wocheperako ndi wosakwana 1.0mm.

3. Zida za alloy sizili zochepa: zipangizo monga carbon steel, zitsulo zosapanga dzimbiri, zitsulo zamkuwa, alloy copper, aluminiyamu, alloy kutentha kwambiri, titaniyamu ndi zitsulo zamtengo wapatali zimatha kupangidwa ndi kuponyedwa mwatsatanetsatane.Pazinthu za aloyi zomwe zimakhala zovuta kupangira, kuwotcherera ndi kudula, zochulukirapo Ndizoyenera kwambiri popanga mwatsatanetsatane.

4. Kusinthasintha kwakukulu kwa kupanga ndi kusinthasintha kwamphamvu.Itha kugwiritsidwa ntchito popanga misa komanso kupanga batch yaying'ono kapena kupanga chidutswa chimodzi.

Mwachidule, kuponya mwatsatanetsatane kuli ndi ubwino wa ndalama zazing'ono, mphamvu zazikulu zopangira, zotsika mtengo zopangira, kuphweka kwa njira zopangira mankhwala, ndi kubweza mwamsanga pazachuma.Chifukwa chake, ili pamalo abwino pampikisano ndi njira zina ndi njira zopangira.

Zowonetsera Zamalonda